- UNCATEGORIZED

- THT Machine Spare Parts

- CONSUMABLES & TOOLS

- FEEDER

- Machine

- SMT SPARE PARTS

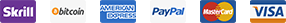

LED PCB Cutter Depaneling Machine

Brand:

A LED PCB Cutter Depaneling Machine is a machine used to separate or “depanel” individual LED PCBs (printed circuit boards) from a larger panel after they have been assembled. In electronics manufacturing, multiple PCBs are often connected on a single panel during production. The depaneling machine cuts these individual boards apart without damaging the components on the boards. This process is crucial for creating finished, stand-alone PCBs that are ready for final testing, packaging, or integration into devices. The machine ensures clean, precise cuts, improving efficiency and reducing manual labor.

Get a free quote

Please feel free to tell us what you need! we are here to help!

Introduction

In the realm of electronics manufacturing, particularly in the production of LED-based products, efficiency and precision are paramount. One critical step in the production of LED PCBs (printed circuit boards) is depaneling, the process of separating individual PCBs from a larger panel once they are assembled. The LED PCB Cutter Depaneling Machine plays a crucial role in this step, ensuring that the separation of PCBs is done quickly, accurately, and without damaging the delicate components on the boards. By automating the depaneling process, manufacturers can improve production speed, reduce labor costs, and enhance the overall quality of their products.

Key Features of the LED PCB Cutter Depaneling Machine

- Precise Cutting Technology The core function of the LED PCB Cutter Depaneling Machine is to make clean and precise cuts between individual PCBs on a panel. This is achieved using advanced cutting mechanisms such as rotary blades, v-scoring, or laser cutting. These methods ensure that the PCB remains intact without damaging sensitive components like LEDs, resistors, or capacitors.

- High-Speed Operation In high-volume production environments, speed is critical. The LED PCB Cutter Depaneling Machine is designed for rapid processing, enabling manufacturers to cut through hundreds or even thousands of PCBs per hour. This speed is essential to keep up with the demands of large-scale LED PCB production and reduce overall manufacturing time.

- Minimal Damage to Components One of the biggest concerns during depaneling is the potential for damage to the components on the PCB. High-end LED PCB Cutter Depaneling Machines are specifically designed to minimize this risk. By using precise cutting methods and automated control systems, these machines ensure that the LED and other components on the PCB are not disturbed, even during the cutting process.

- Customizable Cutting Settings Depending on the design of the PCB panel and the specific requirements of the product, the cutting machine can be adjusted for various cutting depths, speeds, and techniques. This flexibility allows manufacturers to handle different panel sizes, thicknesses, and PCB layouts without compromising on cutting quality.

- Automated Feeding and Handling To further improve efficiency, many LED PCB Cutter Depaneling Machines come with automated feeding systems that move the panel through the cutting area. These systems ensure smooth and continuous operation, reducing the need for manual handling and allowing for higher throughput. Once the panels are cut, the separated individual PCBs are automatically collected and sorted for the next stage in the manufacturing process.

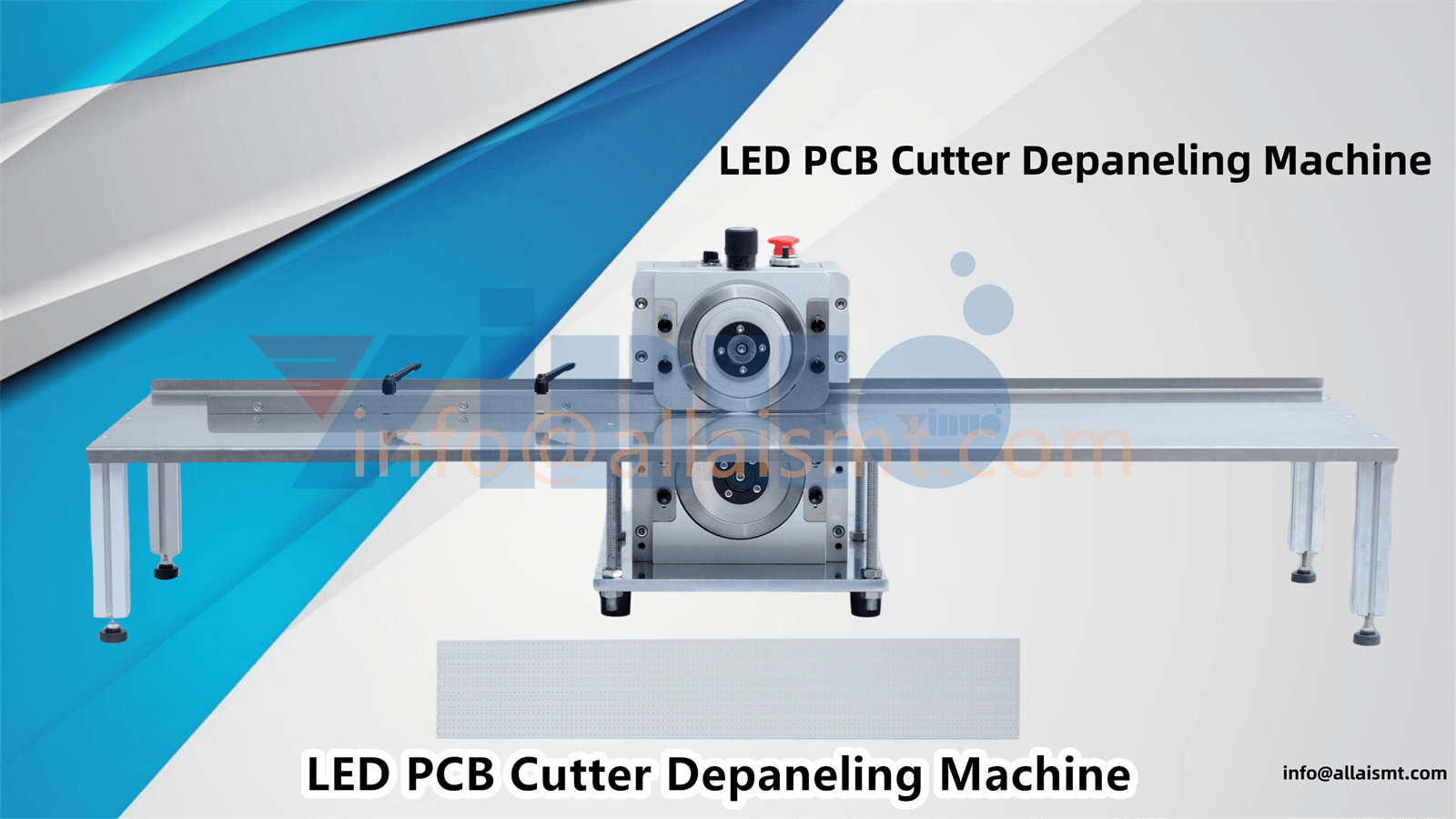

- Safety Features Depaneling machines often include safety features to protect operators from injury during the cutting process. These may include protective covers, safety sensors, and emergency stop buttons. These safety systems ensure that the machine operates in a secure manner, minimizing the risk of accidents in the workplace.

Benefits of LED PCB Cutter Depaneling Machines

- Increased Production Efficiency The automated nature of the LED PCB Cutter Depaneling Machine eliminates the need for manual labor in the depaneling process, speeding up production and reducing labor costs. High-speed cutting capabilities mean that manufacturers can process a large number of PCBs quickly, which is essential in high-volume production environments.

- Improved Quality and Precision Manual depaneling methods, such as hand cutting or breaking the panel apart, often lead to uneven cuts, component damage, and poor-quality boards. By using an automated cutter, manufacturers achieve consistent, high-quality results with every PCB. The machine ensures precise cuts, minimizing the risk of defects such as broken traces or damaged components.

- Cost-Effectiveness Although investing in an LED PCB Cutter Depaneling Machine requires upfront costs, it ultimately leads to significant cost savings. The machine’s speed, precision, and automation reduce labor costs, minimize waste, and lower the risk of product defects. Over time, the return on investment (ROI) is substantial, especially for manufacturers that produce large quantities of PCBs.

- Reduced Risk of Damage One of the primary advantages of using a depaneling machine is the reduced risk of damaging the delicate components on the PCB. Manual depaneling methods can easily result in bent or broken components, leading to costly rework or scrapping of the boards. The cutting mechanisms in the LED PCB Cutter Depaneling Machine are specifically designed to protect the components and maintain the integrity of the PCB.

- Flexibility for Different PCB Designs LED PCB Cutter Depaneling Machines are versatile and can handle a wide range of panel types and designs. Whether it’s a small batch of custom PCBs or a large volume of standard boards, the machine can be adjusted to accommodate different panel sizes, thicknesses, and configurations, making it a valuable tool for manufacturers with diverse product lines.

Applications of LED PCB Cutter Depaneling Machines

- LED Lighting Industry The LED lighting industry is one of the biggest beneficiaries of PCB depaneling machines. From LED bulbs to backlighting panels, these products often require precise PCB depaneling to separate individual units while preserving the integrity of the LEDs. The depaneling machine ensures that the components are not damaged, which is crucial for maintaining the quality and functionality of the final product.

- Consumer Electronics In consumer electronics, many devices use LED technology for displays, indicators, or backlighting. The LED PCB Cutter Depaneling Machine is used to separate PCBs for devices like smartphones, tablets, TVs, and computers, ensuring that each individual PCB is ready for assembly and testing.

- Automotive Electronics Modern vehicles contain a wide array of LED-based electronic systems, including lighting, displays, and control units. The PCB depaneling machine is used in the automotive industry to separate PCBs that are used in these applications, ensuring that the PCBs are cut accurately and efficiently.

- Medical Devices In medical devices, where precision and reliability are paramount, depaneling machines ensure that the LED PCBs used in diagnostic equipment, imaging systems, or medical monitors are free of defects and ready for further assembly.

Conclusion

The LED PCB Cutter Depaneling Machine is an indispensable tool in the electronics manufacturing industry, especially in the production of LED-based products. By automating the depaneling process, manufacturers can achieve faster production times, higher precision, and improved quality control. This results in cost savings, reduced waste, and enhanced product reliability. Whether in the lighting, consumer electronics, automotive, or medical device industries, the LED PCB Cutter Depaneling Machine plays a key role in ensuring that the final product meets the highest standards of quality and performance.

Features of the light strip board splitter:

1. The machine body is made of aluminum alloy, which is lightweight and does not take up space. It is easy to operate and fast.

2. The distance between the upper and lower knives can be accurately adjusted to solve the problem of V-CUT depth, minimize the internal stress generated when cutting the board and avoid tin cracking.

3. The upper and lower circular knives can be accurately adjusted. All PCB boards and aluminum substrates with V-CUT can be used for this machine to cut.

4. The motor is a supporting service for Shanghai famous brands, and the whole machine is easy to maintain.

5. The knife is made of German imported steel and customized by a professional knife-making company in Taiwan. It is wear-resistant and has a long life. The blade can be repeatedly ground and used.

6. The blue powder coating on the surface is a special process and is not easy to fall off.

Mainframe size: length x width x height 285x382x390mm

1.2m stainless steel platform size: length x width x height 1200x500x400mm

2.4m stainless steel platform size: length x width x height 2400x500x400mm

Maximum board length: unlimited

Board speed: 0-400mm/s

Board thickness: 0.8-3.5mm

Using voltage: 220VAC

Machine weight: 70kg

LED PCB Cutter Depaneling Machine (1)

LED PCB Cutter Depaneling Machine (1)

LED PCB Cutter Depaneling Machine (1)

LED PCB Cutter Depaneling Machine (1)