Wave Soldering Titanium Finger: Essential Insights for Electronics Manufacturing

Wave soldering is a widely-used process in electronics manufacturing, particularly for soldering through-hole components to printed circuit boards (PCBs). This method involves the use of molten solder, which is applied to the board as it passes over a wave. One essential component in optimizing the wave soldering process is the titanium finger, a key part of the equipment used during the operation. In this article, we’ll explore what a wave soldering titanium finger is, its role in the process, and why it’s an important piece of the puzzle in PCB manufacturing.

]

What is Wave Soldering?

Wave soldering is a process used to solder electronic components to a PCB. The process involves passing the board over a wave of molten solder, which adheres to the leads of the components and creates strong, reliable solder joints. Typically used for large-volume production of through-hole components, wave soldering is known for its efficiency and ability to produce high-quality results.

What is a Titanium Finger in Wave Soldering?

In the context of wave soldering, a titanium finger refers to a specialized mechanical part or fixture that holds, guides, or supports the PCB as it travels through the soldering process. The name “finger” typically denotes a part that makes contact with the board in a controlled and precise manner to ensure accurate positioning, avoiding any interference with the soldering process itself.

The term “titanium” comes into play because of the material’s unique qualities, which are perfectly suited for the high-temperature environment of wave soldering. Titanium is known for being highly resistant to corrosion, durable, and capable of withstanding high temperatures, making it an ideal material for components that will be exposed to molten solder and the rigors of the soldering process.

Role and Function of Titanium Fingers in Wave Soldering

Titanium fingers are crucial in wave soldering for several reasons:

- Stability and Durability: Titanium’s exceptional resistance to high heat and corrosion ensures that the fingers can withstand prolonged exposure to molten solder without degrading. This durability helps maintain the consistency and reliability of the soldering process over time.

- Precise PCB Handling: During wave soldering, precise alignment of the PCB is critical. Titanium fingers assist in gently guiding the PCB through the molten solder wave, ensuring that the components are properly aligned and that the solder joints are formed without defects.

- Reduced Contamination: Titanium is a non-reactive material, which reduces the likelihood of contamination during the soldering process. This ensures that the quality of the soldering process remains intact and that the boards are not compromised by unwanted materials.

- Improved Efficiency: Titanium fingers are designed to be both robust and lightweight, contributing to the overall efficiency of the wave soldering process. Their durability means fewer replacements and less downtime for maintenance.

- Consistent Performance: With their ability to maintain their shape and structure over time, titanium fingers help maintain a uniform soldering environment, which is crucial for producing consistent, high-quality products.

Why Use Titanium in Wave Soldering?

The wave soldering process involves a high degree of mechanical and thermal stress, and as such, the materials used in the equipment need to meet rigorous standards. Titanium is particularly suited to meet these demands due to its properties:

- Heat Resistance: Titanium can withstand extreme temperatures without warping or corroding, making it ideal for high-temperature soldering processes like wave soldering.

- Corrosion Resistance: In addition to heat, the soldering process exposes parts of the equipment to various chemicals. Titanium’s resistance to corrosion ensures that the fingers last longer and perform better, even in harsh environments.

- Strength and Durability: Titanium is one of the strongest materials available, providing the strength necessary to handle delicate PCBs while preventing damage during the soldering process.

Conclusion: The Importance of Titanium Fingers in Wave Soldering

The role of the wave soldering titanium finger is more significant than it might first appear. By offering unparalleled strength, heat resistance, and precision, these titanium components ensure that the wave soldering process remains efficient, effective, and consistent. Whether you are producing high volumes of electronic boards or seeking the best results in your wave soldering operations, the titanium finger is an indispensable part of ensuring quality and reliability in the soldering process.

If you are involved in the design or optimization of wave soldering systems, incorporating titanium fingers can offer long-term benefits in terms of equipment durability, consistent solder joints, and reduced maintenance costs. As electronics manufacturing continues to demand high precision and quality, titanium fingers stand as a testament to the advancements in soldering technology, offering manufacturers the tools they need to stay competitive in the ever-evolving market.

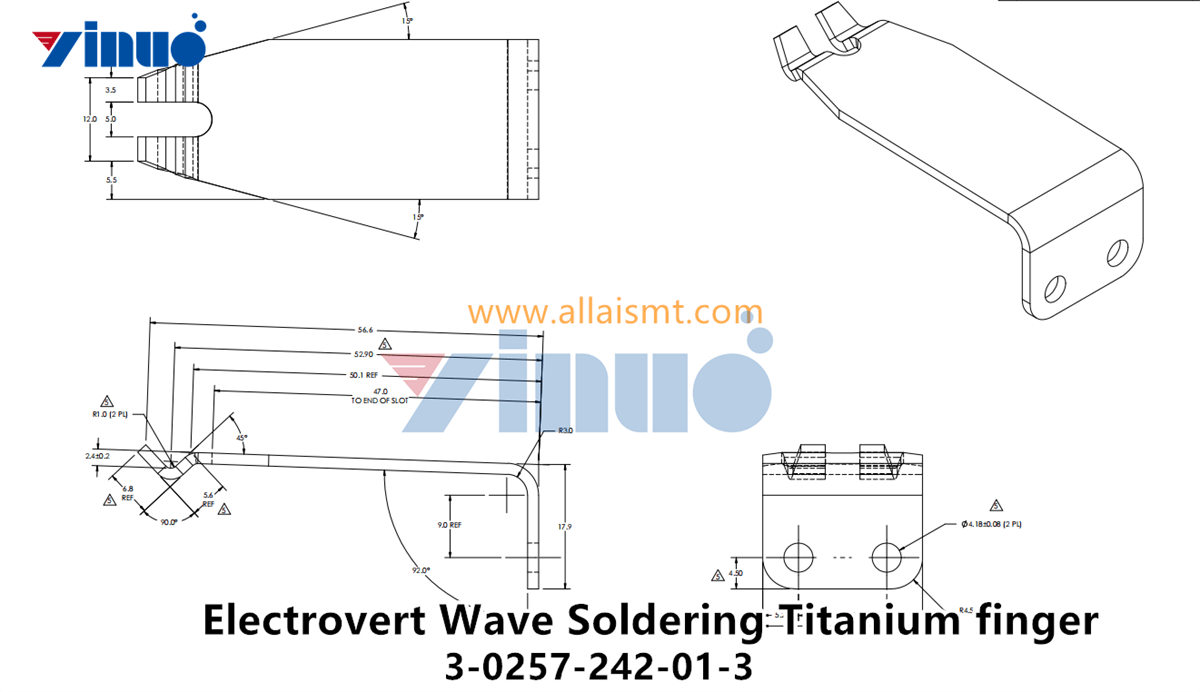

3-0257-242-01-3 ELECTROVERT FINGER,V,GROOVE,RIGID,TITANIUM